how does vapor honing work

Are favorite application is carbs for the finish it provides. It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting.

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure.

. The vapor blasting process provides the. Water abrasive and compressed air are 3 key components to vapor abrasive blasting. It is a surface refinishing process that effectively removes coatings contaminants corrosion and residues without damaging the original surface.

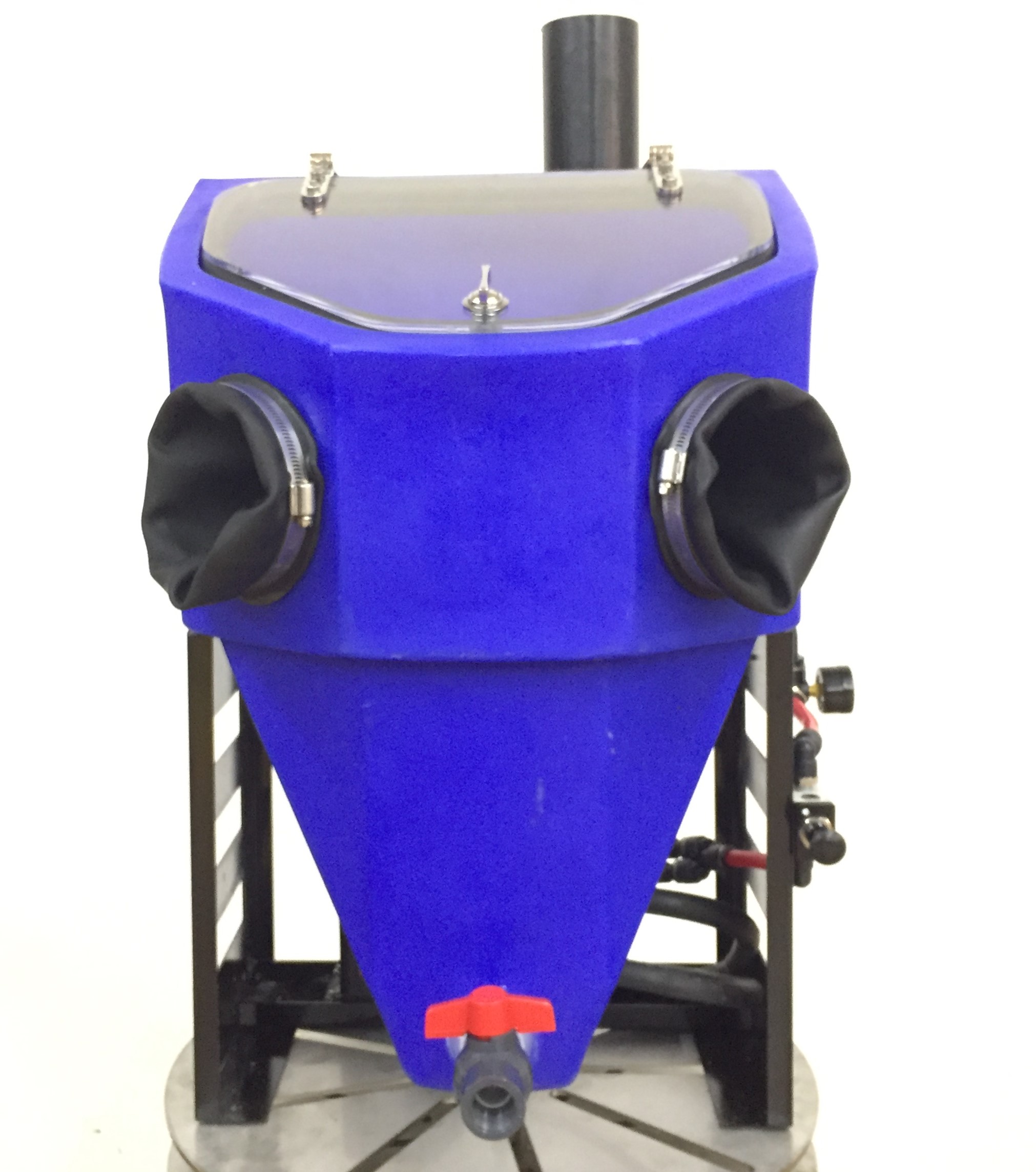

Treat the surface to make it metallurgically clean prior to electro-polishing electro-plating or other coating processes. Vapor honing is also a great choice for removing very tiny scuffs and tool marks as well as for applications that need a satin-smooth finish. Designed to be compact yet powerful MiniMAX is the perfect bench top home hobby wet blasting vapour blasting machine.

Also known as wet abrasive blasting vapor blasting vapor honing dustless blasting or slurry blasting. Vapor honing can be used on almost any surface found on a motorcycle or car including gloss plastic. Less friction means fewer repairs.

These kinematics give this process the typical honing angle. Vapor Honing often known as wet blasting is a technique used to polish precise surfaces. The feed movement causes a radial spreading of the tool whereby the abrasive makes contact with the bore walls.

Supplied as a simple quick to assemble kit youll be up and running in no time. This slurry is mixed into a fluid and evenly mixed as a liquid in the bottom of the hopper. Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like.

Remove machining or directional polish lines or marks on such objects as molds and dies for metal plastics or rubber. Once you concoct your slurry it goes into the sump at the bottom of the cabinet. Vapor blasting goes by many different names.

We normally refer this as the sump. This operation effectively reduces surface friction and heat resulting from normal wear and tear or stress on the material. Makes your old parts look like new.

The Liquid Vapor Honing process is applied to metals for the following reasons. Thankfully vapor honing provides a way of cleaning without damaging metal and other delicate surfaces. No special tools required.

Assemble in as little as just 4 hours. How Do Vapor Honing Machines Work. Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces.

Then you can insert the part through the side door of your vapor honing cabinet. Click to see full answer. Then theres a second hose that brings the water in through the blast nozzle this is called a water injection or that creates a circle of water that blocks some of the dust thats made in the water blasting.

There are hundreds of different applications and abrasive mixtures that can be combined to. Vapor blasting is also commonly known as wet blasting liquid honing vapor honing dustless blasting or slurry blasting. In this manner how does Vapour blasting work.

On aluminum it leaves a finish that looks almost like paint. Wet blasting vapor blasting is a process for removing contaminants from a surface or finishing a surface using pressurized water and abrasive blast media. This is because the water used in vapor blasting creates a cushion between the abrasive particles and the surface.

Depending on your application this will determine your abrasive needed to process your parts. Vapor blasting is the combination of mixing water with abrasive which forms a slurry. This means that the impact of the abrasive is not direct and is therefore gentler on the surface you are cleaning.

The friction decreases because the metal has a smooth surface after a bead blasting treatment. How Does It Work. Combine water and the abrasive for your application and you are ready to begin blasting.

A specially designed high. It is executed by the tool and includes the lifting turning and feed motion. Wet blasting vapor blasting is a process for removing contaminants from a surface or finishing a surface using pressurized water and abrasive blast mediaIf the abrasive media is mixed with water and pressurized in a pressure pot before being propelled through a blast nozzle and mixed with compressed air.

To remove imperfections such as heat treat scaling you add fine abrasives to the water then sprayed onto the material at great speed. Click to see full answer. The key to vapor blasting is that the finish is produced through the flow of water borne abrasive giving a finer finish due to the flushing action of the water.

When youre doing vapor blasting outdoors the abrasive in the machine comes out with the use of compressed air. Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion. While it can handle a wide variety of materials it gives a excellent finish aluminum zinc brass and magnesium.

The vapor blaster uses a liquid barrier on the materials it processes. The liquid is pumped up to the blasting gun and compressed air accelerate the mixture propelling it towards the part. If the abrasive media is mixed with water and pressurized in a pressure.

Wet blasting wet abrasive blasting aqua blasting slurry blasting wet sandblasting dustless blasting and liquid honing. Similarly how does vapor blasting work. Vapor honing uses water and abrasive flowing across the surface to scrub away contaminates rather than directly impacting the surface damaging and removing material.

Water abrasive and compressed air a. Well how it works is t. Vapor blasting also known as wet blasting liquid honing or dustless blasting is a process that uses pressurized water and abrasive material to remove contaminants corrosion residue or coatings from a surface.

An essential feature of the honing process is the process of kinematics. No media is impregnated into the component nor is there any dust created by the break-up of media unlike dry blasting where the finish is produced by sheer force of media impact.

Vapor Hone 1000 Wet Blasting Equipment Blast Wash Systems

Vapor Honing Services What Is Vapor Honing And Does It Work

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Honing Services What Is Vapor Honing And Does It Work

Most Valuable Tool Vapor Honing Technologies Youtube

What Exactly Is Vapor Honing 5 Things You Should Know

Vapor Honing Technologies Lilhonda Com

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Vapor Honing Pdx Vapor Honing Restoration Services

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube

What Is Vapor Blasting Answering Your Wet Blasting Faqs

Slurry Blasting Vapor Blasting Equipment For Sale Vapor Honing Technologies

Vapor Blasting Services Wet Blasting Vapor Honing Technologies

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Vapor Honing Wet Blasting Vapor Blasting Blast Wash Systems